GMC-1311/1614/2518/.... Fixed beam gantry machining center series

Zongheng Machine

The company's main products include gantry machining centers, vertical machining centers, CNC lathes, surface grinders, vertical lifting table milling machines, turret type universal rocker milling machines, etc. The products are widely used in fields such as mold manufacturing, automotive parts, wind power and nuclear power, ocean shipping, military industry and aerospace, and university teaching.

key word:

Turret type milling machine | Rigid mill | Horizontal knee type milling machine

Category:

DESCRIPTION

GMC fixed beam CNC gantry milling equipped with milling, boring, drilling (drilling, expansion, hinge), tapping, countersink and other processing functions. For the different characteristics of customers, optional full closed-loop grating precision feedback system, tool center cooling function,ATC robot hand style, automatic workpiece measurement, tool automatic measurement, 4-axis linkage processing and other functions, customers can enjoy excellent cost-effective configuration, Satisfied with the intimate products. The product specifications and configuration of the leading domestic product structure and technology is mature, product quality and stability, machine torque, fast response characteristics, suitable for automotive, mold, aerospace, packaging, hardware and other mechanical processing needs.

Machine Features

●powerful cutting ability combined with excellent accuracy and performance makes milling and boring easy.

●the spindle head can be equipped with 90° side milling neck with oil pressure locking mode.

●The machine bed, column, crossbeam, saddle and headstock are made of high- strength cast iron with resin sand modeling and reasonable reinforcement structure, with good rigidity and strong stability.

●The main movement adopts wide speed control AC servo main motor, and ZF speed change is selected to make the main shaft output large torque at low speed,which is suitable for heavy cutting, and the constant power at high speed is suitable for finishing.

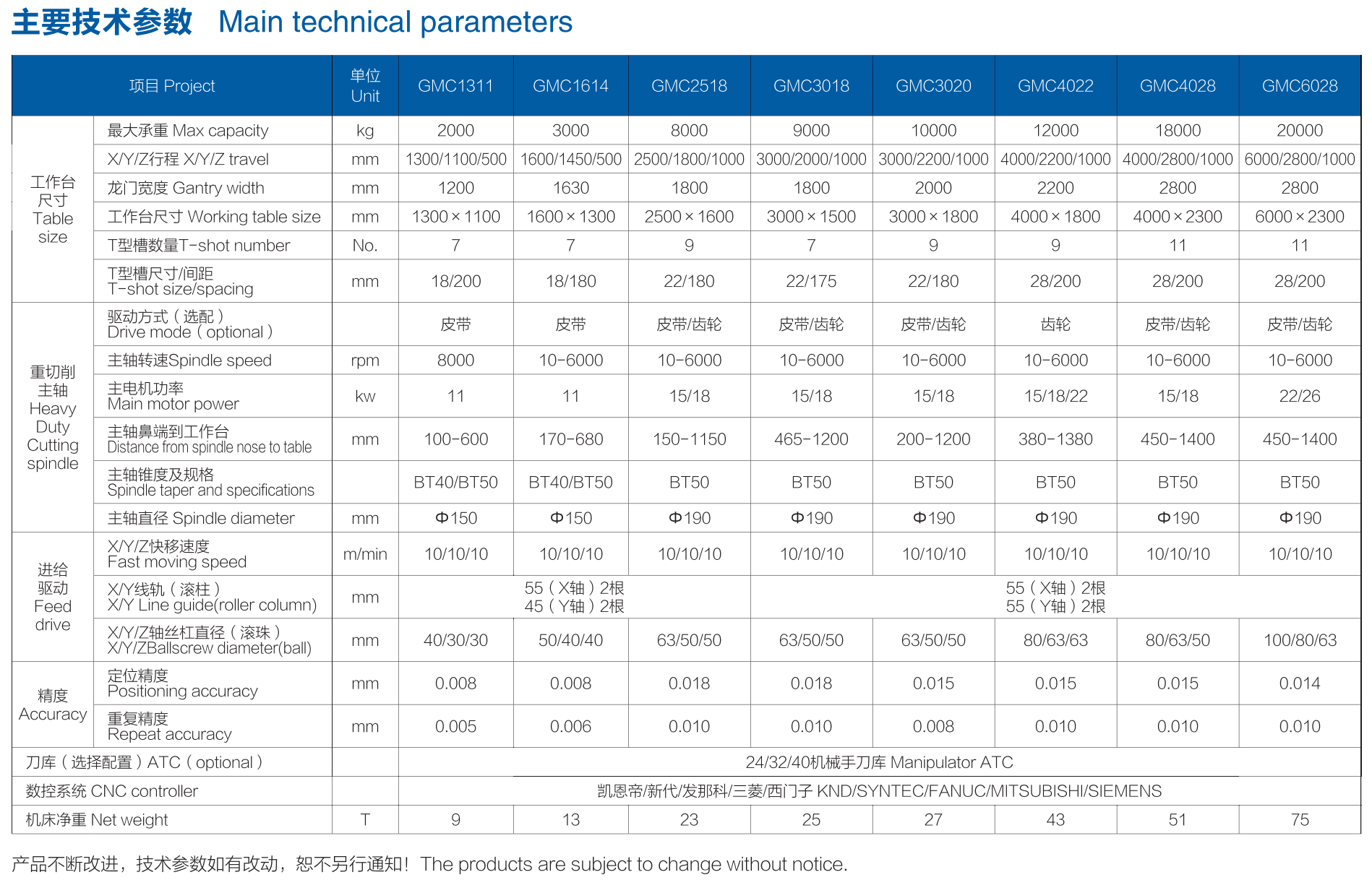

Main technical parameters

A CNC machine tool is an automated machine tool equipped with a program control system. This control system can logically process programs with control codes or other symbolic instructions, decode them, represent them with coded numbers, and input them into the CNC device through information carriers. After calculation and processing, various control signals are sent out by the CNC device to control the action of the machine tool, and the parts are automatically processed according to the shape and size required by the drawings.

CNC machine tools have effectively solved the problem of complex, precise, small batch, and multi variety parts processing. They are a flexible and efficient automated machine tool, representing the development direction of modern machine tool control technology and a typical electromechanical integration product.

Related Products

Welcome to your message for consultation